Project leader

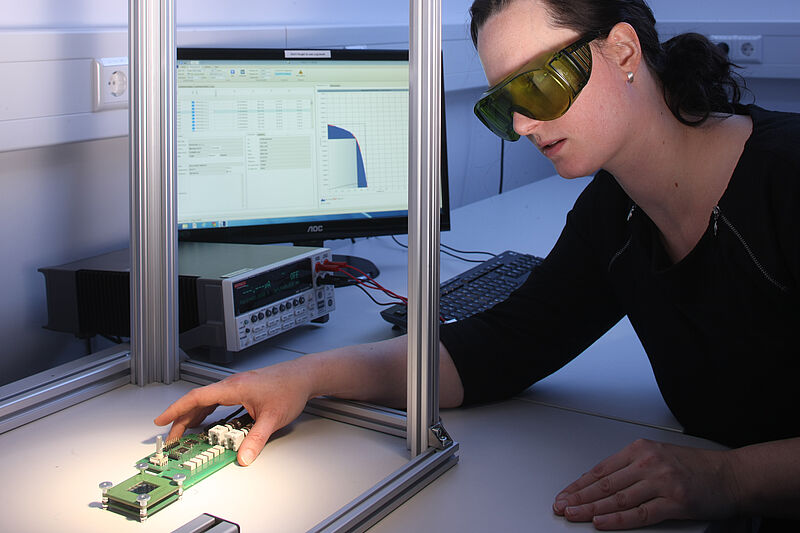

The Pilot Plant

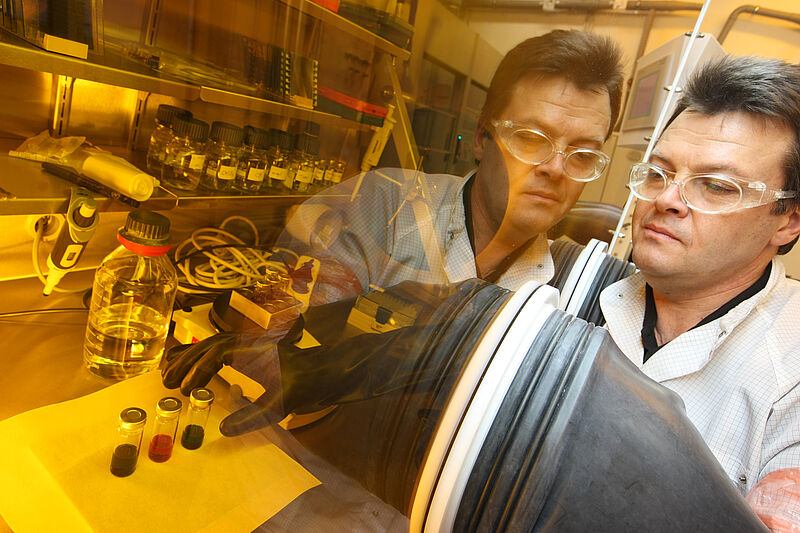

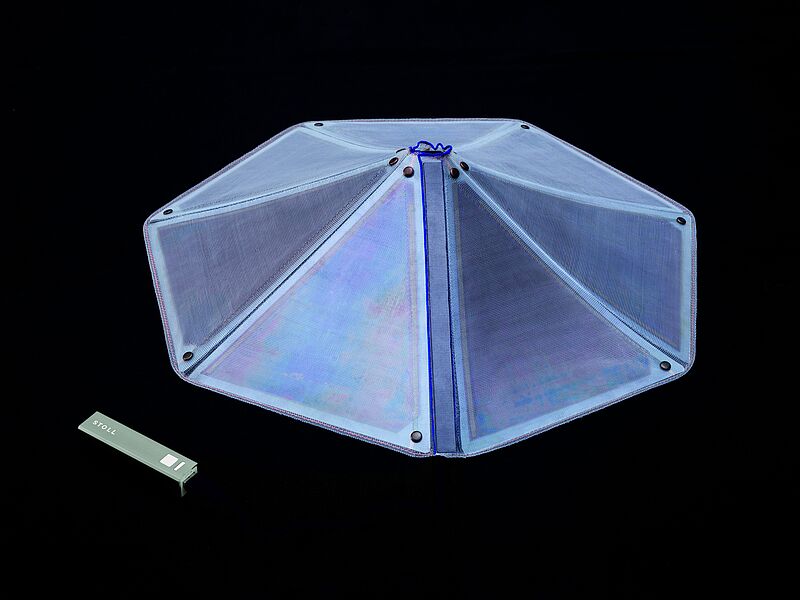

The technikum is the heart of the photovoltaic research and provides a new technology platform for process development. In 2014, all essential equipment was procured and installed at approx. 200 m² laboratory and characterisation area. The equipment enables the possibility for the development of new synthesis methods, which allow the production of larger quantities (litre scale) of inks for roll-to-roll printing. The solar modules are manufactured by combining various printing techniques with laser structuring processes. This makes the manufacturing of complete components in a single operation possible.

- Preparation and characterization of thin solution processed films of small molecules and polymers

- Evaluation of existing and development of new coating and printing processes for organic solar cells and solar modules

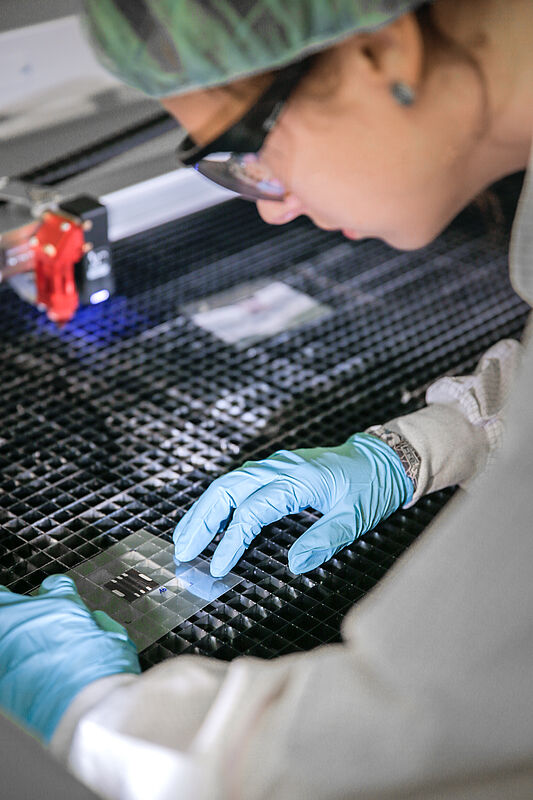

- Analysis and characterization of single layers, multilayers, solar cells and modules

- Production of printed solar cells / modules

- Development of Electrode materials

- Development of structuring procedures and interconnection techniques

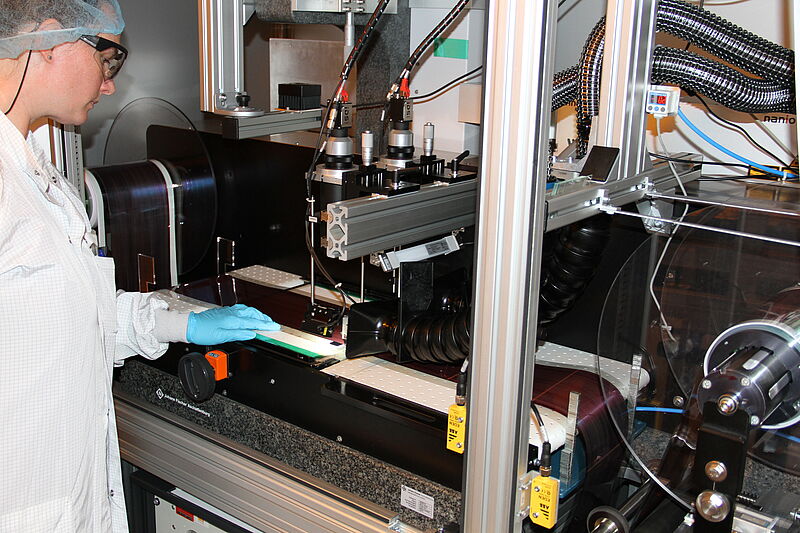

- Scaling of printed cell layers to industrially relevant sizes (approx. 30 x 30 cm²)

- Construction of a roll-to-roll pilot plant for the production of printed solar modules in an inline process and development of coordinated process steps

- Lifetime of Organic Electronics: Encapsulation Processes and Investigations of Ageing Processes

- Materials sciences for organic, inorganic and hybrid components

- Nanotechnology

- Coating and printing methods

- Characterization and analysis of organic and inorganic thin films

- Simulations of the behavior of small molecules and polymers, solar cell and module design as well as flow behavior of inks

- Development of environmentally compatible, green formulations

- Solar cell and module design

- Structuring by means of printing or laser processes

- Printing and coating technology for (opto-) electronic thin-film components

- Conception and production of solar cells and modules by means of printing and coating processes as well as laser ablation

- Characterization of thin film solar cells and modules

- Development of ink formulations

- Scaling of synthesis and printing processes

- Electrical and optical simulation of materials and components

- Lifetime and stability of organic solar modules

- Project management of complex research projects (incl. acquisition of external funds)

- Extensive network in the above-mentioned areas (scientific and industrial), material development and printing processes, solar cells research landscape, industrial partners

- Chemical laboratory for the synthesis of ink formulations

- Glove box for processing various materials that need to be protected from air and moisture

- Flatbed coating machines with squeegee or slot nozzle

- Mini roll coater with slot die and flexography unit

- Ink-Jet Printer

- Screen printer

- Spray coatinger

- Loop-Coater with slot die, UV- and IR drying unit

- Thermal evaporator for the vapor phase deposition of metals

- Roll-to-roll pilot line for inline production of solar cells and modules

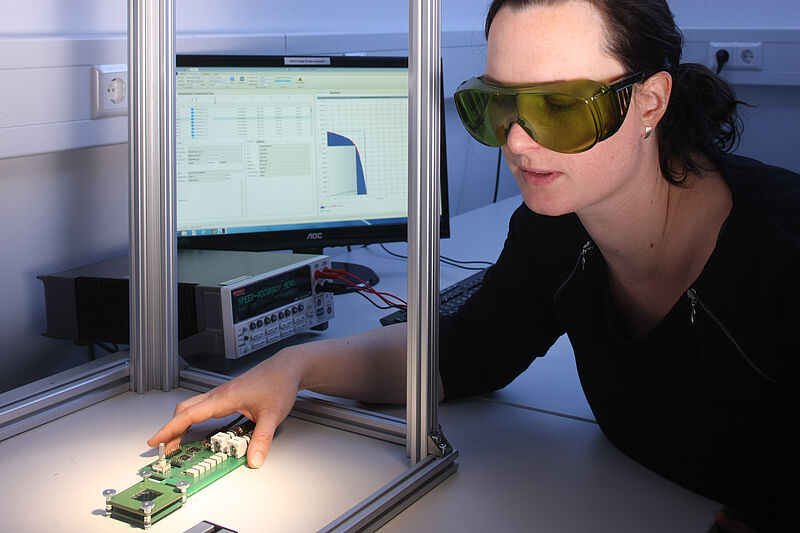

- Femtosecond laser system for structuring modules

- Confocal microscope

- Solar simulator for module characterization

- Evaluation of the printability of new materials for organic solar cells and electronic components

- Development of new printing, coating and testing processes for industrial applications

- Development of green formulations for new materials

- Organic electronics

- Printing and coating technology

- Printed Photovoltaics

- Printed electronics (OLED, display, lighting...)

- Printed membranes/electrodes (fuel cells, accumulators...)

- Printed sensor technology